OUR CO-GENERATION SOLUTIONS

Helping our Customers Achieve Better Cost Efficiency

Co-generation / Combined Heat And Power (CHP)

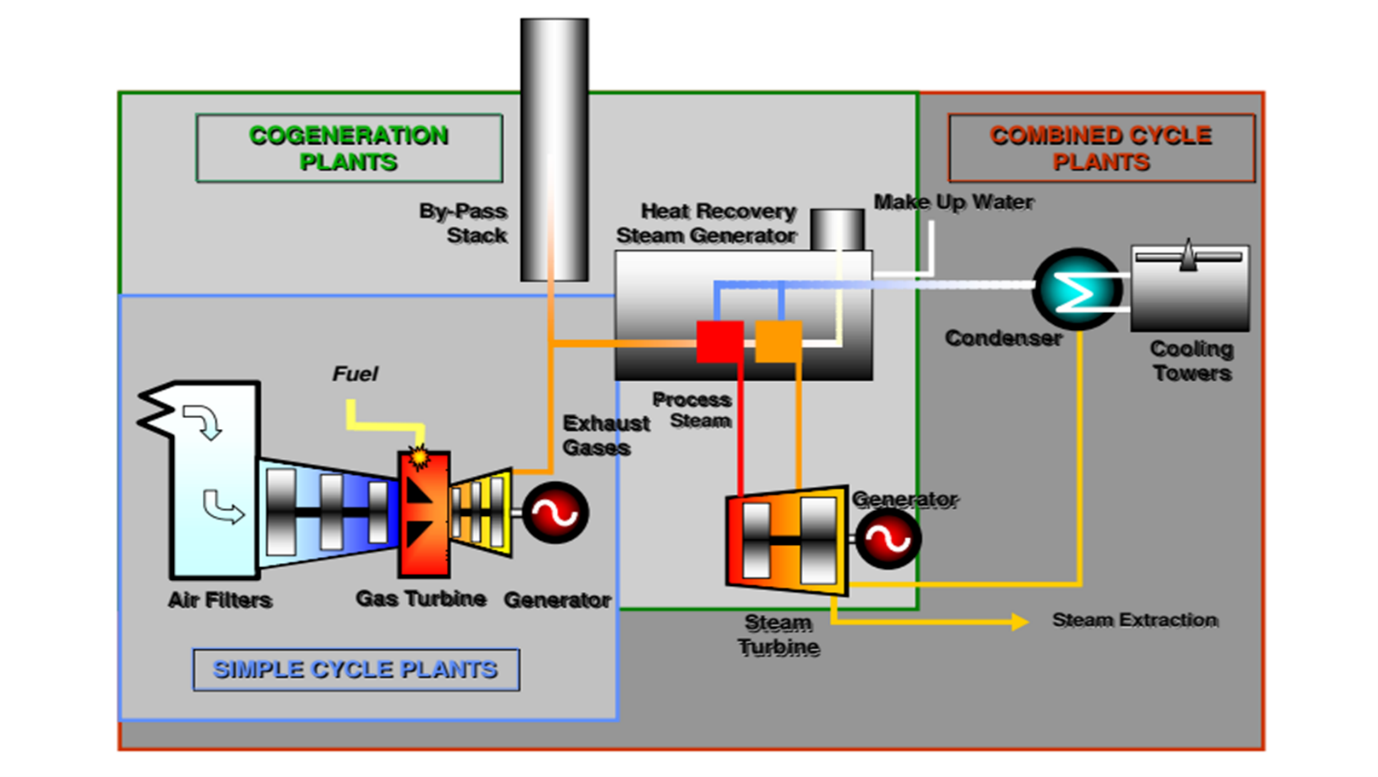

Co-generation or Combined Heat and Power (CHP) is the production of electrical power, hot water and steam to use in production. Utilizing the waste heat generated by a Gas Turbine or reciprocating engine or micro turbine, it provides usable hot water to supplement facilities heat load. A well-designed Co-generation plant can provide efficient energy power while reducing the cost of power.

Trigeneration / Combined Cooling Heat And Power (CCHP)

Tri-generation or Combined Cooling, Heat and Power (CCHP) refers to the generation of electrical power, chilled water and hot water. Introducing an absorption chiller to the system allows the production of both cold and hot water to the power generation process which can be utilized in a building’s HVAC system or utilized in a manufacturing plant.

Co-generation solutions benefits:

Efficiency Benefits

CHP requires less fuel to produce a given energy output and avoids transmission and distribution losses that occur when electricity travels over power lines

Economic Benefits

CHP can save facilities considerable money on their energy bills due to its high efficiency, and it can provide a hedge against electricity cost increases

Environmental Benefits

Because less fuel is burned to produce each unit of energy output and because transmission and distribution losses are avoided, CHP reduces emissions of greenhouse gases and other air pollutants

Reliability Benefits

Unreliable electricity service represents a quantifiable business, safety, and health risk. CHP can be designed to support continued operations in the event of a disaster or grid disruption by continuing to provide reliable electricity.

Courtesy of the EPA

Our EXPERTS are ready to help you

From planning, scheduling and co-ordination between various suppliers, our complex projects consist of experienced engineers and integrators. MYS Engineering also provides specific project management services if required by the client on an ad-hoc basis. This entire process is our standard operating procedure for all our projects following strict procurement guidelines and thorough assessment from quotations to warranties and guarantees.

Get in touch for consultation on the following:

The benefits of onsite power generation solutions for your company

Potential financial benefits using economic modeling

Incentive programs relevant to your business

Consultation on the technical side of your project - fuel types, feasibility studies, equipment and balance of plant selection, and more

Options to deliver your project: purchasing, financing and leasing, engaging a service provider (ESCO, BOO etc.)

How to meet emissions targets

Turnkey Solutions

MYS Engineering Turnkey Solutions are coupled with experienced consultants and contractors in multi-disciplinary fields of engineering

Our core team consists of experienced multinational consultants provide specific advisory and project management services if required by the client to enhance its current plant efficiency in line with our system. In the early stages, our team will provide design and engineering services from early-stage conceptual project planning through detailed engineering packages necessary for the project construction. Our entire team of professionals will work along with clients to identify key parameters and goals as well as obtain information required to initiate the preliminary design phase.

Some of our noteable projects completed

Kiev-CRG Sdn Bhd (Careglove)

Turbine Models

1 X MTU Gas Engine Generator

Installed Capacity

1 X 5.6MW

Commissioned 2021

1 X MTU Gas Engine Generator

Installed Capacity

1 X 5.6MW

Commissioned 2021

Muda Paper Mill, Kajang (Phase I)

Turbine Models

2 X Taurus 60 Gas Turbine Generator

Installed Capacity

2 X 4.8MW

Commissioned 2006

2 X Taurus 60 Gas Turbine Generator

Installed Capacity

2 X 4.8MW

Commissioned 2006

Muda Paper Mill, Kajang (Expansion, Phase II)

Turbine Models

1 X Taurus 60 Gas Turbine Generator

Installed Capacity

1 X 4.8MW

Commissioned 2010

1 X Taurus 60 Gas Turbine Generator

Installed Capacity

1 X 4.8MW

Commissioned 2010

Invest Energy Sdn Bhd (Etika Daires Meru)

Turbine Models

1 X MWM Gas Engine Generator

Installed Capacity

1 X 2.0MW

Commissioned 2019

1 X MWM Gas Engine Generator

Installed Capacity

1 X 2.0MW

Commissioned 2019

Perstima Utility Sdn Bhd (Pasir Gudang)

Turbine Models

1 X Taurus 60 Gas Turbine Generator

Installed Capacity

1 X 4.8MW

Commissioned 2011

1 X Taurus 60 Gas Turbine Generator

Installed Capacity

1 X 4.8MW

Commissioned 2011

Reach out to us

Got a question or enquiry we can help you with? Please reach out to us and we will get back to you

(+603) 7887 0104 / 0105